VA191U14 Project

Study of the process for obtaining methanol, hydrogen and Fischer-Tropsch diesel from syngas obtained from energy crops

Ref.: VA191U14

Introduction

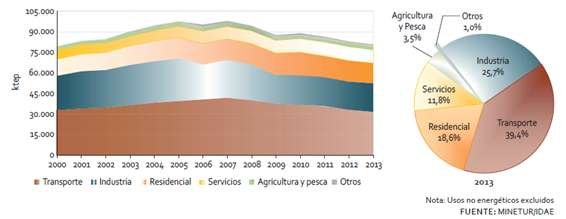

Figura 1. Evolución del consumo de energía final por sectores (2010-2013). (SEE, 2014)

Figura 1. Evolución del consumo de energía final por sectores (2010-2013). (SEE, 2014)

Total consumption of hydrocarbons, oil and natural gas in final energy represents 62.8% of the total in 2014 (SEE, 2014), this figure being higher than the average of the countries in the economic environment, and making it necessary to redouble efforts in energy diversification and saving, to reduce as far as possible this excessive dependence on hydrocarbons, which weigh down the trade balance, depending excessively on the exterior, since the internal production of hydrocarbons does not even reach 0.2% of the needs.

In this context, lignocellulosic biomass gasification processes are among the most promising technologies, as they allow the production of synthesis gas (syngas) that can be used to obtain a wide range of second-generation biofuels (synthetic diesel or Fischer-Tropsch diesel, methanol, hydrogen, dimethyl ether or DME, etc.). In addition, unlike other renewable energy technologies, they allow the use of a wide variety of raw materials (forest residues, herbaceous residues, carbonaceous liquid residues, etc.), which do not compete with food markets (as is the case with biodiesel obtained from vegetable oils).

Another important advantage is its versatility, since syngas can be used not only for the synthesis of biofuels, but also for obtaining other types of compounds (plastic derivatives, ammonia, etc.), as well as for the generation of electrical energy. In addition, the thermal energy of the different process streams can be used to generate heat and cold.

Figure 2. Main routes for obtaining products in Biorefineries based on the gasification process.

However, its development today requires a broad research programme which, among others, must cover the following points:

- Increase the flexibility and versatility of gasification systems in order to take advantage of both herbaceous and woody biomasses and obtain different products in the same equipment. There is little experimentation regarding gasification processes in the same reactor aimed at obtaining different products using different types of raw materials, however, their development will greatly increase the flexibility and viability of these installations.

- Improve gas cleaning systems to meet the high requirements for both its use as synthesis gas and for obtaining electrical energy. Today, in some cases, these requirements have required the use of water washing systems, with the consequent increase in the cost of the process by generating a residue that requires highly expensive subsequent treatment.

- Development of models that allow simulating the complex processes that occur in gasification reactors, as well as in the synthesis processes of different biofuels.

The Project focuses specifically on the study of these lines, developing both at laboratory and pilot plant level a systematic study of the different processes involved (bubbling fluidized bed gasification, gas cleaning and synthesis of 2nd Generation biofuels), as well as their corresponding modeling.

Goals

The main objective of the Project is to contribute to developing a technology that allows the joint or individual production of alternative biofuels (Fischer-Tropsch diesel, methanol and hydrogen) and electrical energy, through the application of gasification processes to biomass from energy crops (thistle and poplar), applying green chemistry procedures that allow the waste generated to be minimized and/or revalued.

The development of biofuels from biomass can be obtained from forestry and agricultural waste, but ultimately they require a constant and stable supply of raw material. In this sense, energy crops play an essential role. Examples of this type of crops are cardoon and poplar, which due to their characteristics can be used in different areas of Castile and Leon.

|

|

|

Figure 3. Biomasses used

Main advances and conclusions.

- Kinetic models of thermal degradation in an inert atmosphere of these two species (thistle and poplar) have been developed, in order to characterize the initial stage of pyrolysis, which is the initial stage of any gasification process in which the initial tars are generated.

Figure 34. Experimental data and model of Tar during thistle devolatilization.

- Gasification tests were carried out in a bubbling fluidized bed, varying the Equivalent Ratio (ER) and the type of gasifying agent, determining the amount of tar generated and the composition of the gas. The main conclusions of this study were:

- By increasing the ER value and therefore the temperature, the total tar concentration decreases.

- The following families also decrease with ER: 1- and 2-ring aromatic compounds, phenol, cresols, oxygenated heteroaromatics.

- As the FE increases, however, the gases concentrate into recalcitrant compounds such as: benzene, naphthalene, and compounds with 3 and more than 4 aromatic rings.

- From the point of view of the gasifying agent and tar production, the one that generates the least amount is enriched air, followed by air and finally the steam/air mixture.

- The use of oxygen comparatively reduces the concentration of recalcitrant compounds.

- These data reinforce the conclusion that the most suitable type of gasifying agent is enriched air, using a stoichiometric ratio of 0.3-0.4.

Figure 4. Bubbling fluidized bed gasification plant and gas scrubber cleaning system used.

Figure 4. Bubbling fluidized bed gasification plant and gas scrubber cleaning system used.

- Tests have been carried out to remove tar residues using various biosolvents, and it was found that the most suitable biosolvent in this case was residual sunflower oil.

Figure 5. Tar retained in oil.

Figure 5. Tar retained in oil.

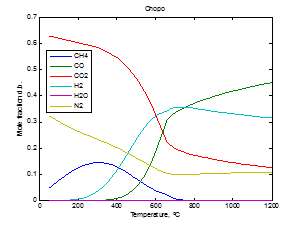

- A modeling of the gasification process for syngas production has been carried out using MATLAB. The developed model is based on non-stoichiometric equilibrium models, since this type of models

allows to know the composition of the gas generated based on the input variables: Biomass composition, type and composition of the gasifying agent, ER ratio, and operating temperature.

Figure 7. Simulation of syngas composition during poplar gasification with enriched air and ER=0.3.

Figure 7. Simulation of syngas composition during poplar gasification with enriched air and ER=0.3.

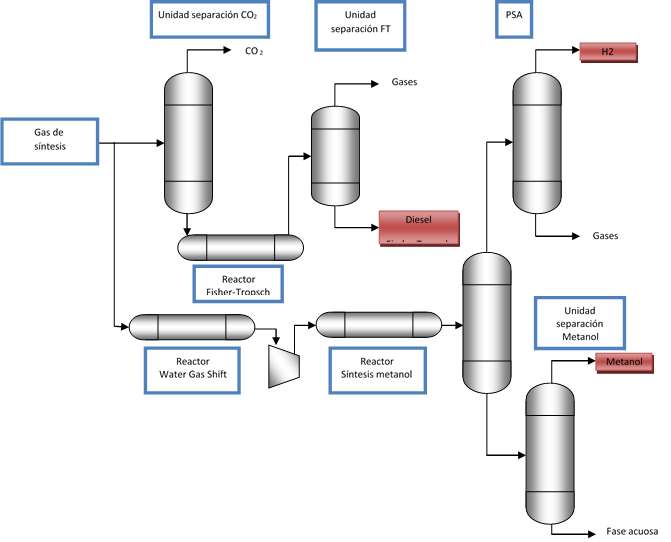

- A model has been developed in ASPEN, which allows simulating the production of the three biofuels (methanol, hydrogen and Fischer-Tropsch diesel) using ASPEN.

Figure 110. Simplified process diagram for the synthesis of methanol, hydrogen and Fischer-Tropsch diesel

- As a result of the project, it is observed that in order to increase the viability of biorefineries and promote their adaptation to the market, it is very useful to design facilities that allow the joint generation of various biofuels.

- The viability of such facilities, however, is estimated to exceed the consumption of 950,000 t/year of biomass, which may be a challenge for their development. This difficulty can be overcome by the joint use of biomass waste and energy crops close to the facility.

Publications

- Steam reforming of model tar compounds over nickel catalysts prepared from hydrotalcite precursors. Díez, A. Urueña, R. Gil, F. Corona, G. Antolín. 5th International Conference on Sustainable Solid Waste Management. ATHENS 2017. 21–24 June 2017.

http://uest.ntua.gr/athens2017/proceedings/pdfs/Poster_Athens2017_Diez_Uruena_Gil_Corona.pdf

- Determination of cellulose, hemicellulose and lignin content of different biomass species by a unique kinetic model from TGA analysis. A. Urueña, D. Díez, G. Antolín, J.A. Conesa. 5th International Conference on Sustainable Solid Waste Management. ATHENS 2017. 21–24 June 2017.

http://uest.ntua.gr/athens2017/proceedings/pdfs/Poster_Athens2017_Uruena_Diez_Conesa.pdf

- The pyrolytic behavior of evolved gases and tar from energy crops. D. Díez, A. Urueña, G. Antolín.

- Pyrolysis Kinetic of thistle D. Díez, A. Urueña, G. Antolín.

References

SEE. Energy in Spain 2014. 2014. Ministry of Industry, Energy and Tourism, Secretary of State for Energy (SEE).

Gratitude.

The Project “Study of the process of obtaining methanol, hydrogen and Fischer-Tropsch diesel, from syngas from energy crops”, with Ref. VA191U14: , has been funded by the Consejería de Educación de la Junta de Castilla y León in the call for research projects to be started in 2014.

Thistle (Palencia)

Thistle (Palencia) Poplar (Soria)

Poplar (Soria)